#Solution ·2025-08-07

For facility managers, air filter procurement for HVAC systems and air purifiers has long been viewed as a routine, low-risk operational expense. However, with soaring energy costs and indoor air quality (IAQ) now a top priority, this mindset is outdated. Every filter you select directly impacts a building’s energy consumption, occupant health, and operational budget. Especially after the EU mandated ISO 16890 compliance, interpreting complex performance metrics and ensuring consistent product quality from suppliers has become a critical challenge. This article dissects the core principles of filter performance standards and quality control, offering a clear roadmap to safeguard air quality while optimizing costs.

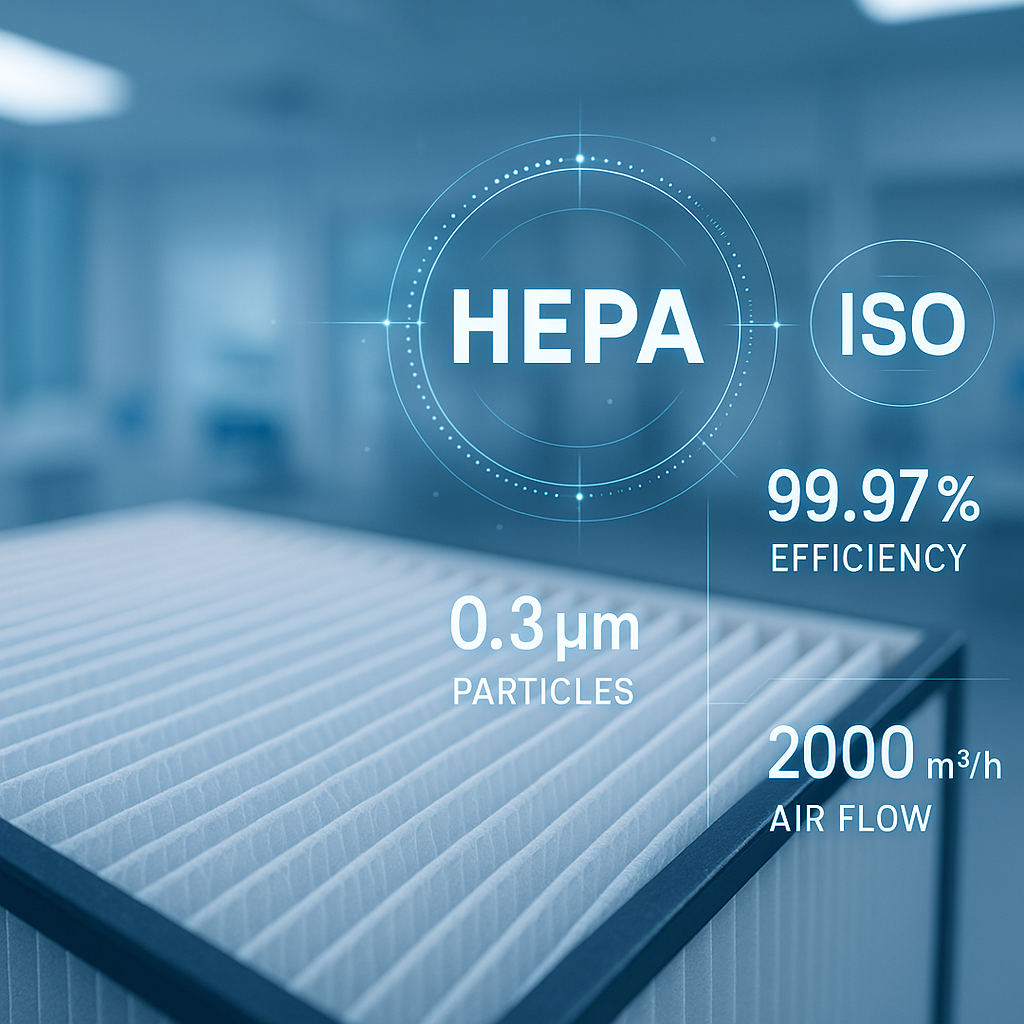

The implementation of ISO 16890 marks a revolution in air filtration. It fundamentally changes how we evaluate and select air filters.

Key Insight: ISO 16890 shifts procurement decisions from "vague grades" to "targeted protection." You can now select filters based on specific space requirements (e.g., protecting employees from PM2.5 exposure).

Higher ePM ratings mean cleaner air but often higher initial air resistance (pressure drop). Increased resistance forces HVAC fans to consume more electricity.

Case Study: A large data center upgraded its HVAC filters from ePM10 60% (formerly F7) to ePM1 80% (high-efficiency filters). While air quality improved significantly, annual energy costs surged by 15% due to excessive pressure drop. This highlights the pitfalls of "over-purification" without balancing filtration performance and energy efficiency. Choosing the "right" filter is far more critical than chasing the "best" one.

Selecting the correct ePM rating at purchase is insufficient. Filters are consumables, and their performance must be guaranteed throughout their lifecycle. Weak quality control risks purchasing products that fall short of claimed specifications.

| Framework Pillar | Strategies & Actions | Key Objectives |

|---|---|---|

| 1. Scenario-Based, Data-Driven Procurement Standards | - Avoid One-Size-Fits-All: Tailor filter specifications to space functions: - General Office Areas: Control allergens and coarse dust → ePM10 ≥ 70%. - High-Density Meeting Rooms/Urban Buildings: Protect against PM2.5 → ePM2.5 ≥ 65%.- Critical Labs/Maternity Rooms: Maximize health protection → ePM1 ≥ 80%. - Prioritize Pressure Drop: Require suppliers to provide initial pressure drop (Pa) at rated airflow. Select models with lower pressure drop while meeting ePM requirements. | - Match performance to needs precisely.- Maximize energy savings at the source. |

| 2. Strict Supplier Qualification & Verification | - Mandate Third-Party Certifications: Require valid Eurovent or equivalent reports for supplier onboarding. - Review Technical Data Sheets (TDS): Ensure TDS includes ePM efficiency, initial pressure drop, recommended final resistance, and dust-holding capacity. - Supplier Audits: For bulk purchases, audit production facilities (onsite or remotely) to assess their quality control processes. | - Eliminate non-compliant suppliers. - Base decisions on reliable, complete data. |

| 3. Continuous Incoming & In-Use Monitoring | - Implement Incoming Quality Control (IQC): Sample-check each shipment for label accuracy, dimensions, and structural integrity.- Install Differential Pressure Gauges: Monitor filter resistance in real-time across HVAC systems. This informs optimal replacement timing and validates filter longevity. - Track & Analyze Data: Record actual filter lifespans and replacement cycles, comparing them to supplier claims for future procurement negotiations. | - Prevent substandard products from entering the system. - Enable predictive maintenance over time-based replacements.- Build a quantifiable supplier performance evaluation system. |

In today’s environment, air filter procurement is no longer a simple "consumables purchase." It demands expertise, data analysis, and rigorous process management. By mastering ISO 16890’s principles, adopting scenario-specific procurement standards, and implementing lifecycle quality control, facility managers can ensure occupant health, unlock energy savings, and achieve optimal balance between cost, efficiency, and sustainability.

#AirFilter #HVAC #ISO16890 #FacilityManagement #EnergyEfficiency #QualityControl #Procurement #IAQ #SustainableBuildings #EuropeB2B

2025-08-12

2025-08-08

2025-08-07

No. 69, Qiguan West Road, Dongqu District Zhongshan Guangdong China

WeChat customer